Inspired by the street type of LA skateboarders and surfers in addition to hip-hop style, small skateboarding shops in NYC began creating their own designs in the Nineteen Nineties. For the photosensitive emulsion to work correctly, it must be left to dry in a cool, darkroom.

DTG however, uses water-based inks which might be semi transparent because of its CMYK system of printing. And while it’s potential to enhance vibrancy by tweaking specifics e.g. adding a white under-base on dark clothes, it typically nonetheless lacks the “pop”. It wasn’t well-liked in its early years, however the fast development of know-how made this printing method more affordable and quicker as properly for producing high-quality prints. These skinny layers of colored vinyl normally are obtainable in two varieties – adhesives ones and non-adhesive ones that require a heat press. While display prints might hold up higher in the lengthy term, you’re limited in the complexity of the design with screen prints. Heat transfers enable extra freedom in color and class making a extra crisp-looking picture .

You can also notice a slight distinction in colours should you print the same picture on a white garment and a black garment. This is as a result of the colored inks soak deeper into the white garment, however on the black garment the colored inks bond to the highest of the white ink layer. Metallic display printing produces an expensive matte finish to prints on fabrics. The first entails using a warmth press to switch your customized vinyl minimize out designs onto the shirt. The second makes use of specialised ink to print the design onto transfer paper, which is then positioned on the shirt and heat pressed to the fabric. Both Digital and screen will look good, crisp and clear as long as the source art is nice.

Overall, the price financial savings is inbuilt as you print extra t-shirts, making display printing a smarter choice https://www.bonestudio.net/types-of-screen-printing/ for designs requiring fewer colors & bigger quantities. The causes these inks are beneficial on Polyester is because at 300 Degrees Polyester Dyes can gas off and migrate into the ink altering the color.

Both of those designs, whereas differing in vibrancy, are what we’d rank on the good-print finish of the spectrum. Now let’s get into the nitty-gritty, the true reason you’re here… Let’s discuss bad prints.

For prints requiring bigger dimensions or particular placement, display screen printing is extremely beneficial. DTG printing is finest fitted to 100% cotton and blends with high cotton content. Because of this, particular blends and styles of clothes may be incompatible with this printing technique. Our DTG companies are priced at a flat price, so the absence of a setup and screens makes it far less expensive for many who solely need a handful of shirts.

Screen print is massively versatile in ink variations and technical capabilities. Digital printing’s blues and violets simply don’t look good on an beneath base. It additionally doesn’t have the specialty inks display printing has like metallics, glow at midnight and UV sensitive colours. The colour vary is greater than adequate for most jobs, however ultimately screen print wins out because of its higher capacity to match more of the visible spectrum and more accurately.

I was fairly lucky to go to good faculties with sturdy female lecturers also. Cal State Long Beach has plenty of great professors that helped me achieve my skills and path throughout my time there. If I hadn't taken graphic design and printmaking I would not be at household.

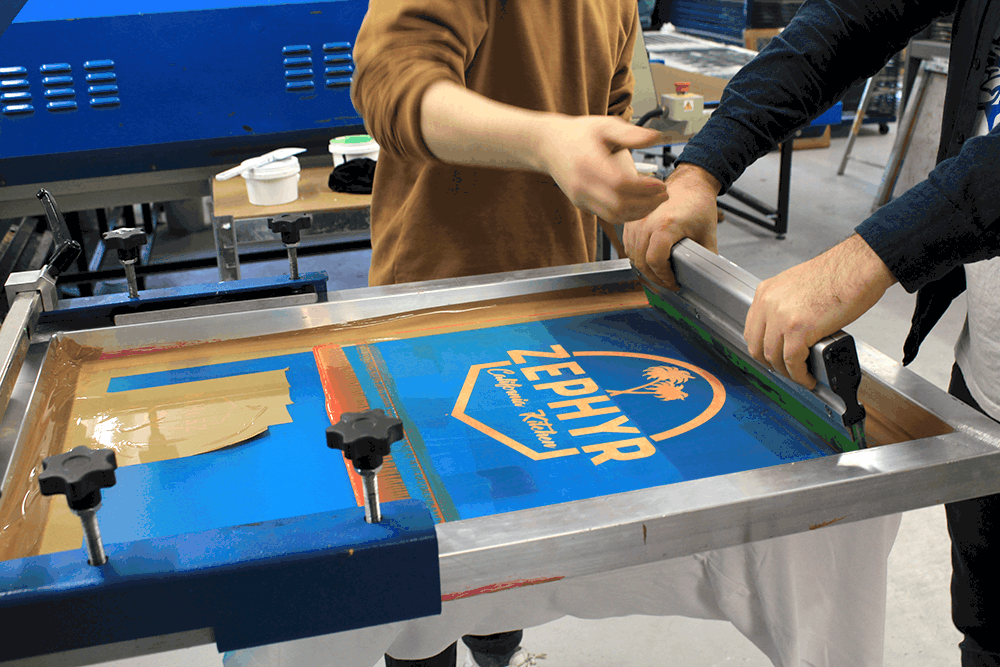

And if you have any questions on heat transfer vs. display printing or other imprint methods, give us a call! Our pleasant and educated workers is pleased that will assist you discover the best possible imprint and item on your distinctive situation. The ink is extracted by way of the template using a knife or foam software, producing a single layer of the design with full and saturated colour. This process implies that screen printing is healthier suited to certain kinds of t-shirt designs.

One purpose a print looks more matte is as a end result of shirt’s texture. When a printer prints the ink into the shirt’s fibers more, the ink molds itself to the shirt's fibers, there’s no flat floor. Traditionally printing a vintage print is a superb example of a matte print. With our White Ink Management System it's attainable to print on any color t-shirt or garment. CMYK colours are provided using a bulk ink system the place every shade is saved in a refillable cartridge or bottle. MESA sells solely the best high quality inks designed specifically for garment printing, which is why we only carry Dupont and Image Armor brands of inks.

The technique of achieving that is referred to as the simulated course of. You don't want to worry such as you would when utilizing a different printing method. This printing additionally has low setup costs, perfect for a one-time manufacturing. DTG and screen printing share the most common features, but they also have notable differences that you have to consider before selecting your business sort. For occasion, DTG is good at printing bulk t-shirts; therefore, when selecting which methodology to go for, you need to be certain that you select the strategy to swimsuit the variety of orders.

While both kinds of inks are durable, Plastisol ink has the status to be probably the most sturdy, nonetheless, some components must be taken into consideration. For example, Plastisol ink is thick and might withstand several washes before fading, although, Plastisol inks are inclined to crack when uncovered to excessive warmth.

C&W Screen Print is proud to announce the addition of our digital printing division. The DTG machine is great for brief runs of full color that might be a better alternative to display printing. Our Roland Versacamm 45 inch printer delivers outstanding shade on indoor/outdoor banners and signs and might gang print logos for decals and stickers. We can print multi-color logos on the Roland and warmth switch them directly to garments and gadgets that cannot be screened. Another option for merchandise that aren't properly suited for the usual display screen print or embroidery processes. Such as 2-ply shorts, jackets, swimsuits, outsized bags, or small totes. In these cases, if the artwork is just too detailed to use our Digital Transfer methodology, we use this other heat press process.

This process could be more time-consuming for designs which have many colors; nonetheless, screen-printed artwork tends to final much longer than heat-pressed artwork. It also requires extra chemical substances and gear for it to work.

This is because, within the display screen printing process, each tone is printed utilizing a special screen. Similar to regular switch papers, an image is utilized to a particular plastisol switch paper first and is subsequently transferred to the material utilizing a heat press machine. In this technique, use an inkjet or laser printer to print your picture on the special “transfer papers” – a skinny piece of paper coated with wax and pigment. Then use a heat press machine to transfer the image onto clothing, canvas, or any other surface.

Also like an workplace printer, the design and setup is basically handled on a computer, which permits for terribly detailed images in a really short time. This is a process that's just like a bigger format ink-jet printer. It permits us to print virtually any art, or image immediately on almost any 100 percent cotton or 50/50 mix garment.